OEM-Level Reconditioning

Catalytic Testing

Measuring Catalytic Performance of Cleaned Exhaust Components

Diesel Oxidation Catylists (DOC) | Coated DPF

New DOCs / DPFs

During the Engineering-Design-Certification cycle, the Catalytic Performance of new DOC and coated DPF is tested under laboratory conditions to certify that the wash coat quantity and precious metal blend is sufficient to keep the engine exhaust going out the tailpipe within emissions specifications. (isn't that a mouthful?)

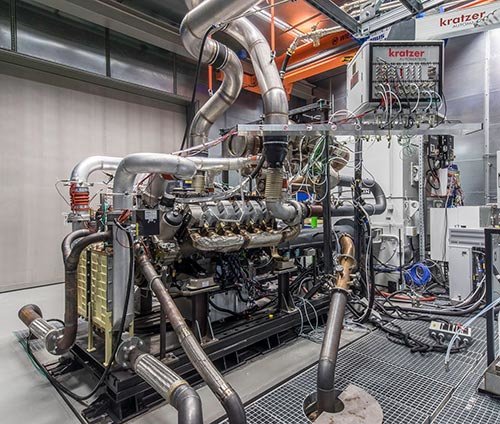

(Sample only - Kratzer-Automation)

Typically these filters are installed on a laboratory diesel engine (dyno) from the factory and specialized, lab-grade instrumentation measures the performance. Dyno testing is done under extremely controlled conditions and each test can take days, weeks, or even months depending on the tests being performed. Temperature and exhaust gas composition are carefully and continously monitored under different load and other conditions to validate the design and wash coat composition.

While great for certifying a design, these conditions do not work to test 5, 10, or 50 DPF per day in a cleaning center, to say nothing of the fact that most cleaning centers don't have a spare $250,000 to $500,000 engine dyno just laying around.

Used/Cleaned DOCs / DPFs

Unlike the design and certification process where a single filter can be tested for months, a cleaning center performing catalytic testing needs to test multiple filters per day or shift. Obviously requires a different approach.

A REMAN-Level certification program requires:

- High volume - Testing 100% of cleaned DOC or Coated DPF per day

- Testing Methodology - Compare/contrast used part performance to new

- Accurate Testing - Measure actual catalytic reactions in real-time

FSX began development of our own catalytic testing capability to meet the needs of our OEM Reman Cleaning center over 10 years ago. Our catalytic test benches have benchmarked and certified tens of thousands of DPF and DOCs processed through FSX and and OEM Reconditioning programs. Every DPF and DOC can be tested and benchmarked against performance of new OEM filters. Having our own catalytic testing capablities have allowed us to develop custom chemical blends to clean and restore catalytic performance to DPF and DOC, which has been independently verified by OEMs.

Tech Note

Catalytic Light-Off VS Light-Out

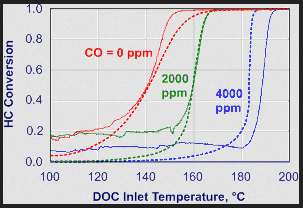

- Temperature vs Catalytic activity - Catalytic coatings only perform when hot - meaning that the engine and exhaust system have to be up to full, normal operating temperature. An exhaust system at idle is significantly cooler than one under heavy load. Outside air temperature and other factors can also influence the exhaust system temperature.

- "Light Off" temp - is the temperature at which 50% conversion efficiency of the washcoat is achieved also referred to as T50.

- "Light Out" temp - is the temperature at which washcoat conversion efficiency falls below 50%. Although closely related and have a strong correlation, Light-Off and Light-Out values are not identical.