FSX TrapRinser™

Stage 3 Heavy Duty Wet Wash DPF Cleaner

- What is Stage 1, 2, & 3? (click here to find out!)

Part of the FSX Family of Cleaning Systems

- The FSX TrapRinser™ uses air and water flushing to safely remove ash and soot from tough to clean DPF.

- Cell by Cell scanning ensures every cell is clean

- Visible cleaning process

- Prevents hydraulic pulse fracturing

Fully visible cleaning lets you KNOW when the job is done!

Wet cleaning options for OEMs, FSX RECON Center, and

Private Fleets since 2009

Private Fleets since 2009

Get a quote on the FSX Cleaning System today!

Scanning Air Knife Flush

Our air-assisted flushing quickly and efficiently removes dissolved ash without the dangers of hydraulic fracturing.

Competitor solutions attempt to ONLY wet clean a wet filter. Loose soot and ash creates sludge inside the filter when combined with water, creating a larger pressure barrier that risks hydraulic fracturing.

Removing loose soot and ash with the FSX TrapBlaster prior to wet cleaning reduces hydraulic force during wet cleaning, protecting your investment.

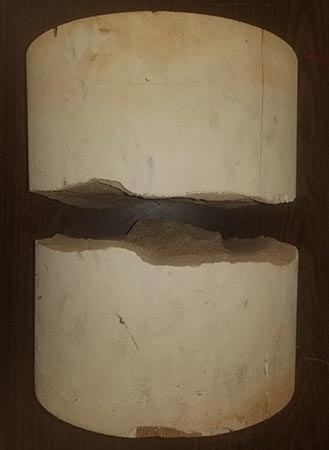

Visible Cleaning Process

Most DPFs are completely clean in 20-25 minutes. However every DPF is different, and the visible cleaning process allows the operator to see when the cleaning is complete.

Unlike competitor products, you KNOW the filter is clean when the "mud" stops flowing!

Each Cell Cleaned

Competitor products clean the entire filter at once and "appear" clean when water finds the "easy" path through the filter, leaving hard to remove ash behind.

The TrapRinser's air-knife cleans each cell individually with air-assisted water to safely flush dissolved ash from the filter. You KNOW when the ENTIRE filter is clean!

(Nozzle shown retracted)

Prevents Hydraulic Fracturing

Competitor products - even those using water and air - apply their cleaning force to the entire filter at the same time. When applied to the entire brick, there is no "safety valve" or escape path for high pressure, and this is applied to the entire brick, causing fractures of the ceramic substrate. Any existing small cracks are easily made larger.

FSX Air-Knife scanning uses air directed at individual cells to assist water flushing the ash out of the cells. If those cells are plugged, the air safely escapes to adjacent cells, preventing excessive force that causes hydraulic fracturing.

PLC Driven Automatic Operation

* - Fully automatic operation, but can be easily adjusted to focus clean on heavily loaded areas for a custom cleaning.

* - Adjustable nozzles allow access to hard to reach flanges and recessed cavities.

Fully adjustable for filter height to 36" and 20" diameter.

TRAPRINSER REQUIREMENTS:

Air Supply:60 CFM/125 PSI of dry air delivered to TrapRinser

Water Supply:10gpm /38lpm of water at 50psi / 3.45 bar delivered to TrapRinser

Air Compressor: Minimum 60 CFM, 125 PSI, 15 HP (11.25 KW):

(Larger air compressor may be required depending on compressor manufacturer, air dryer used, pipe configuration and altitude.)

Air Dryer: High Efficiency (Required) – desiccant style or refrigeration style for 60 CFM/1700 l/min at outlet

Water Pipe Diameter: 1 ½” ID delivery line

TRAPRINSER SPECIFICATIONS:

Dimensions: 85"H x 48"W x 30"

Weight: 1300 lbs

Electrical: Standard outlet 120 Volt, 1 ph, (TBD) 20 amp. UL controlled

Water supply:

1" (2.5cm) inlet line

10 gpm (38 LPM)@50 psi required

(15 gpm/57 LPM recommended)

Ventilation Exhaust:8" duct capable of exhausting 400 CFM (Stainless steel)

Approximate Shipping Weight: 1500 lbs

Copyright © 2016 FSX Equipment, Inc. & FSX Inc. All Rights Reserved